Sustainability is the new standard businesses should strive for and additive manufacturing, through its methods and materials innovation, can facilitate businesses towards that shift.

An increasing number of businesses are adopting sustainability as a business strategy and the reason is clear. In a recent study by technology giant IBM, it was found that consumers are increasingly considering beyond cost comparisons in their purchases and over 70% of consumers prefer sustainable or environmentally responsible goods.

With such customer behavioural trends, adopting sustainability as a business strategy can help improve brand image and provide businesses with competitive advantages.

Furthermore, a shift to sustainability brings about a myriad of other benefits such as improving risk management, inspiring optimisation efforts, increasing efficiency, attracting investments, qualifying for grants and satisfying stakeholders.

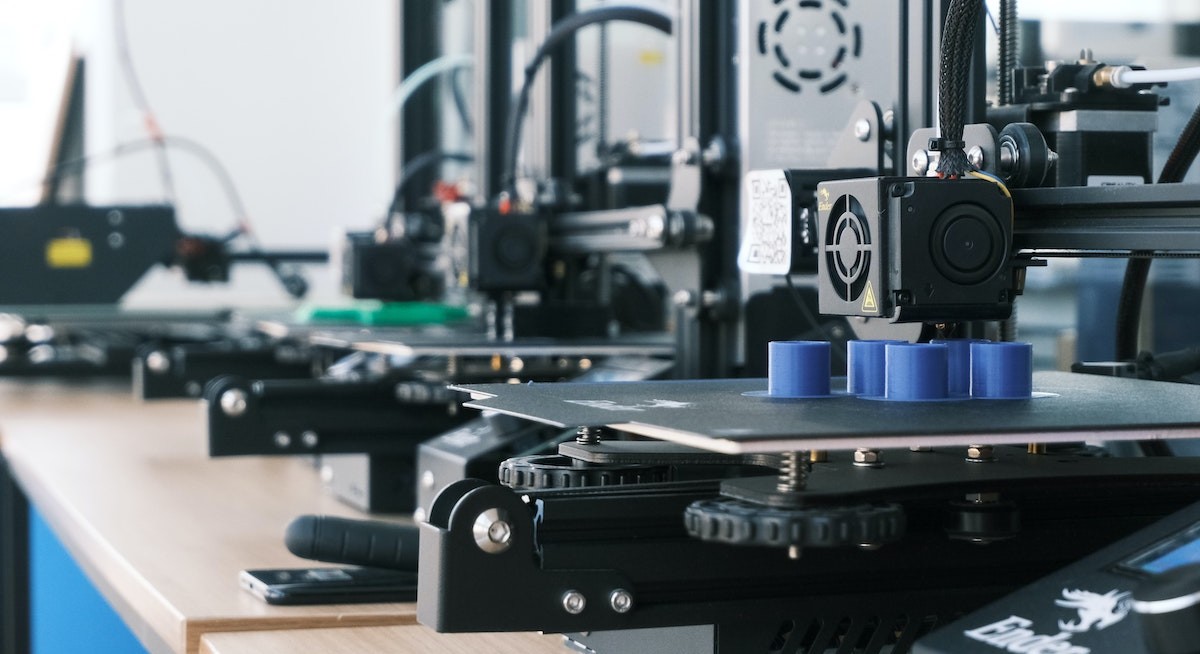

Implementing additive manufacturing into a manufacturer’s business operations can also help them achieve sustainability and reap the benefits that arise. According to Research and Markets, the additive manufacturing or 3D printing sector in the Asia Pacific region is forecast to rise by 21.4% within 2020 to 2030, with a total addressable market cap of US$58.83 billion ($79.5 billion).

Manufacturers would be privy to leverage this booming trend, with two primary areas that additive manufacturing can value-add to businesses and sustainability are through its manufacturing method and the highly innovative manufacturing materials.

Additive manufacturing is undertaken through layer-by-layer production and hence, the accumulation of scrap material is being eliminated. This is ideal for sustainable applications in prototyping as well as in the manufacturing of jigs and fixtures.

Along with digital manufacturing, additive manufacturing facilitates the development of a sustainable global supply chain. Instead of shipping raw materials globally for production, only digital files need to be delivered with additive manufacturing.

With new technologies like generative design and computerised topology optimisation, state-of-the-art products can be created efficiently with sustainability being considered at the early stages. Light weighting of products and bill of materials (BOM) consolidation reduces material usage, while maintaining its functionality.

See also: The data centre conundrum: Balancing demand with sustainability

Based on its manufacturing method, additive manufacturing allows businesses to reduce waste and hence save on material expenses. Businesses should also further venture into partnerships with Additive Manufacturing Networks, which will enable them to design products in one geographic location before producing and distributing in other locations to best serve the end customers’ needs.

By doing so, they can capitalise on overhead cost-saving opportunities through a shortened supply chain. This all culminates in the sustainable operations of a manufacturer, paving the way for businesses to reap the benefits of sustainability.

Manufacturing with recycled materials

The technology adopted in additive manufacturing accelerates innovation in utilising materials that contribute to sustainable business operations. Recycling is the key concept in materials innovation for sustainability in additive manufacturing, which employs the usage of filaments made of recycled materials in its production.

The Armor Group, for instance, produces recycled filaments for additive manufacturing made from used inkjet plastic cartridges. Upon using recycled materials, businesses take responsibility for the end stage of the product lifecycles, as opposed to traditional product life cycles where landfills are situated at the end stage.

While additive manufacturing faces some challenges in uptake due to the limited types of materials that are applicable, the future looks promising with increased innovation for materials that accommodate manufacturers’ needs and regulations.

By allowing the usage of recycled materials into production cycles, additive manufacturing facilitates businesses to produce sustainably and oftentimes, in a less costly manner as recycled materials are cheap and relatively lightweight. Upon undertaking this, businesses are enabled to manufacture responsibly, prolonging the material lifecycle.

With the myriad benefits that accompany a sustainable business practice, manufacturers should shift towards adopting such a strategy. An exemplary way to support that transition would be with the integration of additive manufacturing, which promotes responsible production and sustainable practices that benefit both the environment and businesses.

Raja Parthiban is an additive process engineer at the Jabil Additive Manufacturing Centre in Singapore

Photo: Unsplash