Power issues

Meanwhile, Shi found it necessary to explain what caused the 1HFY2021 earnings to drop. To recap, the company is organised into three business units. The largest contributor in terms of revenue and operating profit is that of advanced materials, which provides the coating services to the parts that are then used by other manufacturers. In 1HFY2021, revenue increased by 18% y-o-y to $76 million, but adjusted ebitda fell 4% y-o-y to $28 million. ebitda margins also fell to 37% for 1HFY2021 from 46% in 1HFY2020.

While demand increased from the so-called 3C (computer, communications and consumer electronics) and automotive sub-segments, supply chain disruptions caused by a global shortage of semiconductors, hampered production. If Nanofilm’s customers could not secure sufficient chips in time, then they would not require much of other components as well.

Nanofilm also incurred higher costs related to the equipment qualification process for a new plant in Shanghai. Shi explains that the new machines being installed use high-tension power lines instead of normal power supply lines. Besides having to get relevant approvals from the city authorities, the installation had to be carried out by a government-approved contractor. This, coupled with Covid-19-related curbs, led to delays. Furthermore, Shi also reveals there was a “timely and pressing demand” from Nanofilm’s customer to qualify 60 new pieces of equipment coating equipment in the new plant. To meet the project delivery deadline, the company rented diesel generators to supply the power needed, thereby incurring extra one-off costs in terms of fuel and equipment rental fees.

In addition, there were costs involved from new projects that have yet to enter mass production and the mix of products sold during the half-year happened to offer lower margins too.

During 2HFY2020 and 1HFY2021, the company added 64 coating machines, making it a total of 186 units. While that increased total production capacity by more than half, the utilisation rate for 1HFY2021 did not increase in tandem but instead dropped from 73% for 1HFY2020 to 61%, which is lower than its own long-term utilisation rate target of around 80%.

The second significant business unit is called industrial equipment, which makes the coating machines for both Nanofilm itself and external customers, where the services business model “may not be feasible”.

Relative to the advanced materials business unit, sales figures for this business unit tend to be lumpier and smaller. Revenue for 1HFY2021 was up 81% y-o-y to $19 million, with a total of 16 machines produced, down from 23 in 1HFY2020.Out of the 16, external sales increased to six from four in 1HFY2020 as customers’ capital expenditure increased, especially from those in the glass lens mould and precision engineering industries. The business unit’s adjusted ebitda for 1HFY2021 was $5.9 million, up 67% from $3.5 million recorded in 1HFY2020.

The third and smallest business unit is called the nanofabrication, described by Shi as the “new baby in the family”. This unit underperformed because a customer, which had been placing orders since the second half last year, halted volume production early this year and the replacement to take up the freed capacity could not be found in time. For 1HFY2021, revenue for this business unit dropped y-o-y from $3.4 million to $1.8 million, registering an adjusted loss before interest, tax, depreciation and amortisation of $0.9 million.

Nevertheless, Shi says there is a “very strong product pipeline” for multiple projects to make “high volume, high margin” parts for two major customers. The first will start by the end of the last quarter this year and another to follow early next year. “We expect to start a very good business with nanofabrication,” he says.

‘Positive and constructive’ Shi assures investors that the company remains on track. “There is no fundamental change in the position of the company’s performance. We are all aligned with its future strategy and growth.” He refers to the extra costs incurred in 1HFY2021 as “positive and constructive” spending that will translate to revenue into the second half of the year. “We are already in the second half of the year and the ramp-up started in June,” he says. The pick-up in business is expected to gain momentum until January before the seasonal slowdown takes place again, which will then be used by the company to focus more on development activities for the next high season. Explanations and outlook aside, does Shi think the market has overreacted to the earnings? “Events of these two days have really let us realise that there is a certain gap to be patched and we need to really enhance our capability to talk to the market and make ourselves more transparent. So, this is really the major lesson learned,” says the former professor. Shi adds that the company has no control over how Nanofilm’s share price moves but will continue to focus on growth, innovation and value creation. “We need to learn how to co-exist with the marketplace and how to guide and communicate to the public and our investors. When we realise that this gap exists, we will take immediate action and measures to rectify it,” he says.

‘Positive and constructive’

Shi assures investors that the company remains on track. “There is no fundamental change in the position of the company’s performance. We are all aligned with its future strategy and growth.”

He refers to the extra costs incurred in 1HFY2021 as “positive and constructive” spending that will translate to revenue into the second half of the year. “We are already in the second half of the year and the ramp-up started in June,” he says. The pick-up in business is expected to gain momentum until January before the seasonal slowdown takes place again, which will then be used by the company to focus more on development activities for the next high season.

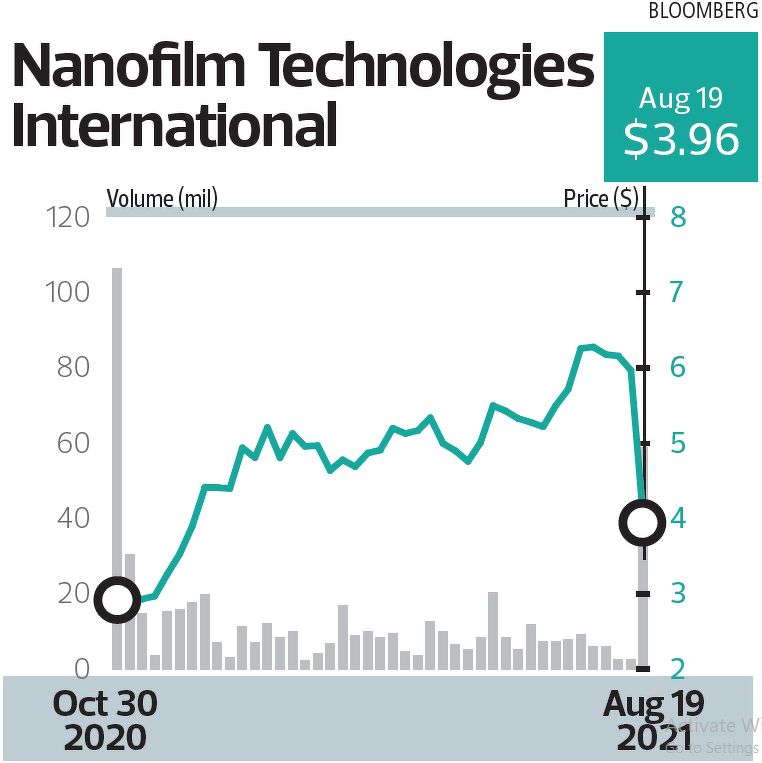

Explanations and outlook aside, does Shi think the market has overreacted to the earnings? “Events of these two days have really let us realise that there is a certain gap to be patched and we need to really enhance our capability to talk to the market and make ourselves more transparent. So, this is really the major lesson learned,” says the former professor. Shi adds that the company has no control over how Nanofilm’s share price moves but will continue to focus on growth, innovation and value creation.

“We need to learn how to co-exist with the marketplace and how to guide and communicate to the public and our investors. When we realise that this gap exists, we will take immediate action and measures to rectify it,” he says.

Sidebar: A homegrown unicorn forged in NTU labs

Nanofilm Technologies was founded in 1999, riding on Shi Xu’s proprietary carbon-coating technology that is just three to four nanometres thick, which also explains the company’s name. Shi drew on expertise from various disciplines including materials sciences to electrical and mechanical engineering to create his own coating process known as the Filtered Cathodic Vacuum Arc (FCVA) technology which offers a layer of protection from material wear and tear and reduces friction.

Shi’s launch customer was Hitachi, which was then a leading hard disk manufacturer. The coating was applied to the moving parts in a hard disk. His list of customers gradually grew to include the likes of Fuji Xerox, Canon, Nikon and Ricoh Co. Today, Nanofilm serves a wide customer base consisting of companies from the computer, communications and consumer electronics (3C), automotive, precision engineering, and printing and imaging industries.

Coating mechanical and electrical parts is not a new concept. For years, steel has been coated with chrome or ceramics. Nanofilm differs by using carbon, which is known for its hardness as well as its friction-reducing properties. When applied to critical components such as piston rings in a car’s engine, the film can help reduce wear and tear and energy wastage. Furthermore, the coating can have decorative properties too. An extra layer of shine or a smooth texture can be added to make an electronics gadget visually more appealing.

Earlier on, Shi had focused on making the machines used in the coating process. However, he soon expanded into providing the coating service as well. By doing so, the company enjoys a recurring income stream, presumably less lumpy than the machine orders. In 2017, when Shi won that year’s EY Entrepreneur of The Year award, the company was still privately held but already generating revenue of around $100 million. Shi was also mulling an IPO at that time, as he told The Edge Singapore in an interview then.

Nanofilm’s IPO last October checked several boxes among investors. For one, with more than $500 million raised, this valued the company at more than $1 billion at its IPO trading debut, making it one of the largest non-REIT issues in recent years. Nanofilm is also a technology company — a welcome change from the parade of banks, property developers and REITs that have dominated the Straits Times Index. Furthermore, Nanofilm is a homegrown company that Singaporeans can be proud of. Shi is from China but a former professor at Nanyang Technological University who developed patents forming the core intellectual property of Nanofilm from within the labs of the university.

Cornerstone investors at Nanofilm’s IPO included Aberdeen Standard Investments, AIA Investment Management, Credit Suisse, Eastspring Investments, Employees Provident Fund Board, JPMorgan Asset Management, Lion Global Investors, Nikko Asset Management and fund management entities linked to the Capital Group — all of which totalled 7.07%.

Finally, there is also Temasek Holdings, which holds Nanofilm through a couple of different entities such as Fullerton Fund Management and Venezio Investments, with a total deemed interest of 6.26%, according to the company’s annual report. Shi himself holds a direct stake of 7.7% and a deemed stake of 47.18%.

Sidebar: Temasek JV could open up H2 fuel market

On July 19, Nanofilm Technologies announced the formation of a joint venture called Sydrogen Energy with substantial shareholder Temasek Holdings to mark a “strategic entry” into the so-called hydrogen economy, possibly opening up a new market for the company.

The JV is formed amid a global push for greater sustainability and hydrogen-fuelled vehicle and machinery is seen as one of the viable and greener alternatives to fossil fuel in use for centuries.

Sydrogen will have its own management team, chaired by James Rowan, who was initially Nanofilm’s lead independent director before being redesignated as a non-independent, non-executive director.

Rowan is familiar working in a technology-focused company headed by a high-profile founder. He was, at various points in time, the executive director, COO and CEO of the Dyson Group, famous for the line of vacuum cleaners and other household products whose core technologies were invented by founder James Dyson. Sydrogen’s CEO is Dev Rudra, who was previously with Pratt & Whitney and General Electric Co.

Under terms of the JV, Nanofilm will hold the majority 65% stake while Temasek, which has been actively investing in ESG-themed companies and industries in recent years, will invest an undisclosed amount of cash to own the remaining 35% stake. Nanofilm will contribute its proprietary technologies and capabilities, and pump in $21 million in cash. For now, a total investment of some $140 million has been planned for the JV, mainly for R&D and the construction of production capacity.

“This further penetration of the clean energy market with Temasek is another growth avenue for the group,” says DBS analyst Ling Lee Keng.

So, what is the game plan for Sydrogen? The first focus, as described by Ling, is to apply Nanofilm’s own filtered cathodic vacuum arc technology in the development of protective carbon coatings for metallic bipolar plates of fuel cells and electrolysers. “Compared to conventional technologies, Nanofilm’s coating technologies and production processes are more durable, corrosion resistance and cost-effective,” notes Ling, adding that possible applications include passenger and commercial vehicles, light-powered mobility solutions and stationary power. “Target markets include China, whereby the government policies strongly support the development of a hydrogen economy starting with fuel cell electric vehicles,” she adds.

Besides the hydrogen JV, Nanofilm is already doing its part for sustainability as well. For example, it now makes a type of piston ring for the automotive industry, which claims to have about 30% lower emissions and energy loss relative to conventional ones.

We are entering this economy, this industry at the right time,” said Shi in the Aug 18 video call. Products are being developed and expected to be qualified by a customer by the end of the year, and production will commence in the second half of next year. The company is also in talks with other potential customers.

Shi is upbeat that the hydrogen venture will soon help drive growth in the foreseeable near term. “We anticipate this area of work will increase tremendously very, very quickly over 2023 all the way to 2025. So this will be another new bright growth point for the company,” he says.